Shake-out systems

Shake-out systems

The demolding machine allows a mold to be destroyed after it has been poured and cooled in order to extract the part.

Demoulding of foundry molds from 200 kg to 50 T fixed, frame in hand or other handled by lifting means.

3 models are available:

- TZ horizontal grid machines : Mold feeding is generally done by lifting and handling: the parts are removed manually or

mechanically.

- TP devices with inclined grid : The molds are fed by lifting and translation, but more generally they are brought by pusher cylinder or other automatic system. The unloading of the parts is done continuously towards the front where they are recovered either in parts boxes or by a metal conveyor.

- TBZ machines with horizontal or low upward slope grid : This is a machine with an alternating straight trajectory directed forward and inclined to the horizontal. The control mechanism is double unbalanced. The upstream feed of the machine is done either by direct vibration of the molds, or by breaking on the fixed cradle, or by dumping clods. The vibrator is always placed above.

Industries

- Foundry

- Transformation, etc.

Characteristics

- Acceleration: 5G

- Surface area: TP and TZ from 0.5 to 13.5m²/floor

- MULTIPLE TZ DECODERS : juxtaposition of 2 or 4 simple TZ machines on the same base (Duplex or Quadruplex).The capacities of the juxtaposed machines are added. Note: for resin sands, the capacities are reduced by approximately 20%.

- TBZ from 1 to 13.5m²/floor

- floors: from 1 to 2 floors

Highlights

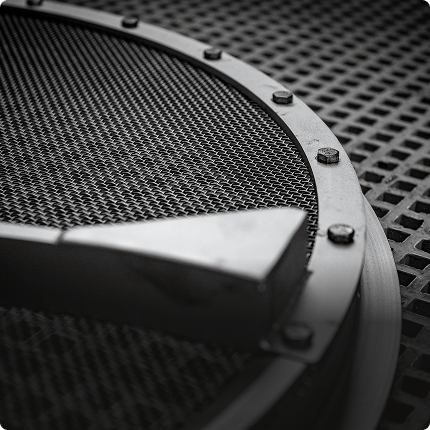

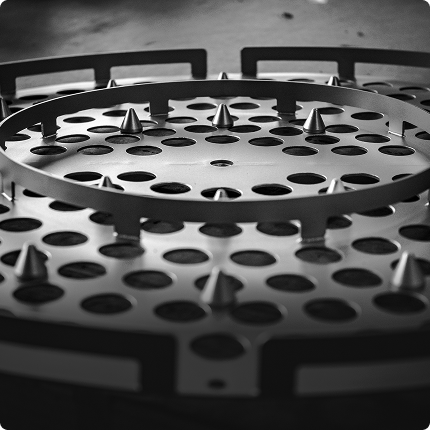

- Robust sander receiving at its upper part, the separation grid, a narrowed section to center the sand.

- A base resting on the ground, generally above a sand discharge conveyor belt.

- An elastic suspension system supporting the body and the base .

- A vibrating mechanism , the vital element of the machine.

- In fact, the various types of de-coilers vary mainly in their type of mechanism, and therefore in their mode of vibration.

Applications type

- Foundry sand

- Separation of rooms, etc.

Options

- Perforated sheet metal

- Longitudinal bar grid

- Crossbar grille

- Progressive slotted and bar grille

- Grid with progressive slots and undercut bars (prevents jamming of parts), etc.

Perfect integration into your projects

The longevity guarantee

Flexible operation

Accessible adjustment parameters

A manufacturing quality known and recognized since 1929

Predictive

maintenance with remote monitoring

maintenance with remote monitoring