OUR solutions

Sieving materials

from 0 to 2mm

![]()

ATEX

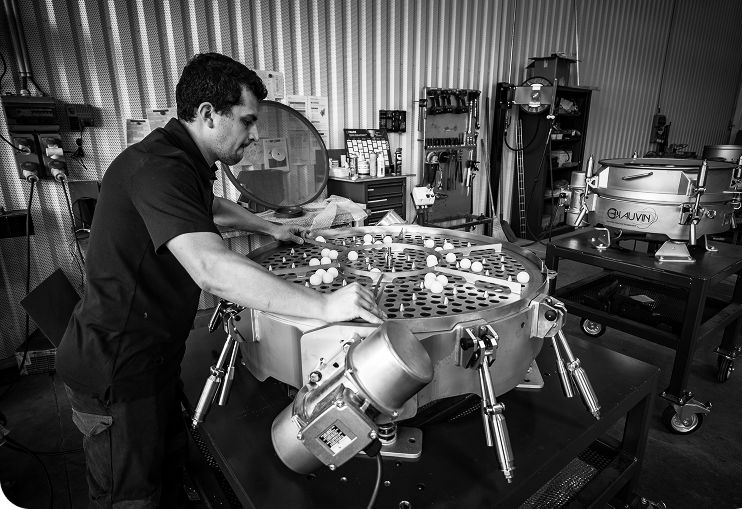

Sifter Giraplan®

It is used for selective or safety screening of powder and dry granules in many industries.

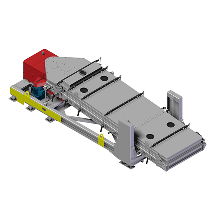

Gyratory sifter SIFT®

Precise particle size distribution of powders or granules for all kind of industries: chemistry, food, fine metallurgiy, sand, wood, etc.

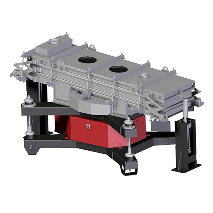

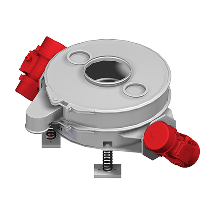

Circular sieve CS®

It is used exclusively for safety screening and the removal of impurities.

Circular sieve RS®

Fine particle size selection of powders or granules, dry or wet.

The benefits for your industrial processes

The advantages of mechanical vibration separation technology

Safety and standards

Securing and conforming manufacturing processes

Simplicity

Simplification of material preparation circuits

Flexibility

Flexibility and customization of equipment

Productivity

Improving your company's productivity

Processing and recycling

of various and specific materials

sort precisely

Separating your product into distinct clusters

economy

Reduction of production costs

ecology

Dust management and environmental protection

Automatisation

Automation and industrial integration

Need advice ?

We help you find the right product

Because every customer and every use is different, our expert and passionate team supports you at every stage of your needs and the life cycle of your equipment, from diagnosis to after-sales service.