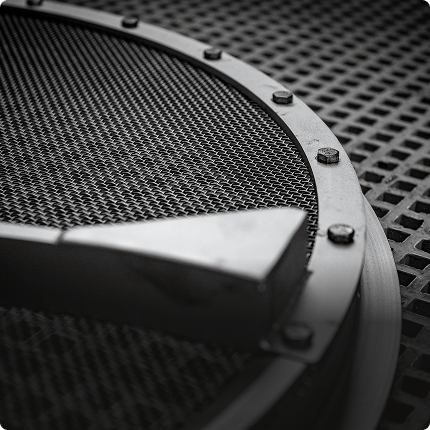

Round Sieve CS

Round Sieve CS®

It is used exclusively for safety screening and the removal of impurities. Generally, this device is particularly suitable for the food and pharmaceutical industries as well as for powder metallurgy.

Compact circular vibrating sieve for removing foreign bodies or agglomerates in low percentage (‹5%) for all types of powdered products, aggregates as well as for liquids /solids. Safety filtration.

ATEX

6 diameters are available:

CS 20 = 0.03 m²

CS 40 = 0.13 m²

CS 60 = 0.31 m²

CS 90 = 0.63 m²

CS 120 = 1 m²

CS 150 = 1.65 m²

CS 180 = 2.5 m²

Flow rate: from 10 kg/h to 50 T/h

Industries

- Agri-food

- Pharmaceutical

- Cosmetic

- Chemical

- Paint

- Metallurgy, etc.

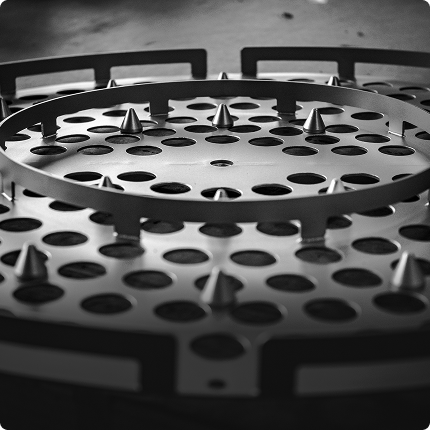

Characteristics

- Inox 304/316L

- Electropolished, brushed, mirror-polished finish

- With or without side exit

- One-piece, open ferrule with cover, height of xxx mm, etc.

- Standard or special inlet and outlet diameter

- Input and output: central or offset

- Handles, lifting lugs, inspection hatches, orientation guide, etc.

Highlights

- Modular design with one or two unbalanced motors

- Tool-free disassembly

- All parts in contact with the product are removable

- No retention area

- Optimal containment and sealing

- Unlimited locations

Applications type

- Milk powder

- Flour

- Sucre cristal

- Cacao

- Dextrose

- Starch

- Metal powder

- Pigments

- Active ingredients, etc.

Options

- Steel/stainless steel mobile support

- Ultrasonic unclogging system

- BIL-VIB unclogging system (balloons)

- ATEX/FDA Certificates

- Painted steel or stainless steel base

- Painted or stainless steel engines

- Washing nozzles

- Polished, electropolished, mirror polished finish

Possible evolution

- CS 60 PT : for sieving powders in a pneumatic suction conveyor in the diluted phase.

- CS 60 BAG : specially developed for the safety screening of materials packaged in 25 kilo bags.

Perfect integration into your projects

The longevity guarantee

Flexible operation

Accessible adjustment parameters

A manufacturing quality known and recognized since 1929

Predictive

maintenance with remote monitoring

maintenance with remote monitoring