Giratory sifter SIFT ®

Giratory sifter SIFT®

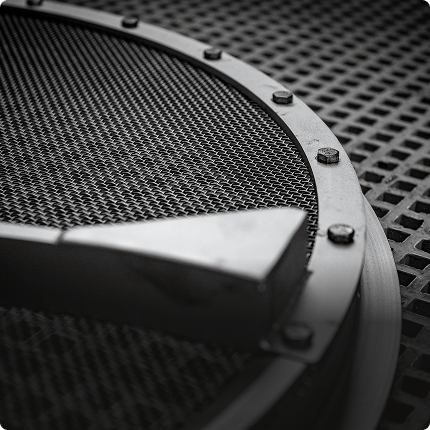

Fine granulometric selection of granules or powders for all types of industry: chemicals, food, fine metallurgy, sand processing, sawmills, etc. Rectangular box screen, with gyratory movement, driven by a single or double balancing mechanism depending on the model, placed under the screening box .

This rectangular sifter with horizontal circular movement allows the product to be distributed evenly and regularly over the entire screen.

The product moves from the inlet to the outlet thanks to a slight slope of the sitting box (1°30, 2°30, 3°)

Flow rate: from 10 kg to 5 T/h

3 models are available:

- 7 XKM/XLM = 0.7 m² (500×1400 mm)

- 14 XKM/XLM = 1.4 m² (700×2000 mm)

- 28 XKM/XLM = 2.8 m² (1000×2800 mm)

Industries

• Food industry

• Cosmetics

• Chemicals

• Paint

• Metallurgy

• Wood, etc.

Characteristics

• 304/316L/Aluminium stainless steel

• Polished, brushed, mirror-polished finish

• Closing by handles, tie rods, pneumatic cylinders

• Standard or special inlet and outlet diameters

• Handles, lifting lugs, inspection hatch, orientation guide, etc.

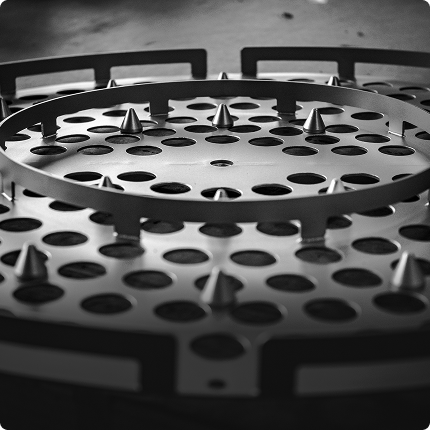

• 1/2/3/4-level configuration

Highlights

- The SIFT movement is very suitable for screening fibrous, stringy and all powdery products due to the almost non-existent vertical movement reducing the phenomenon of pitting and clogging.

- Series changes (screens) are simplified thanks to the pneumatic opening system available as an option.

Applications

• Milk powder

• Flour

• Crystal sugar

• Wood fiber

• Plastic granules

• Pigments

• Lactose, etc.

Options

• Ultrasonic unclogging system

• BIL-VIB unclogging system (balloons)

• O/F by pneumatic cylinders

• ATEX/FDA certificates

Perfect integration into your projects

The longevity guarantee

Flexible operation

Accessible adjustment parameters

A manufacturing quality known and recognized since 1929

maintenance with remote monitoring