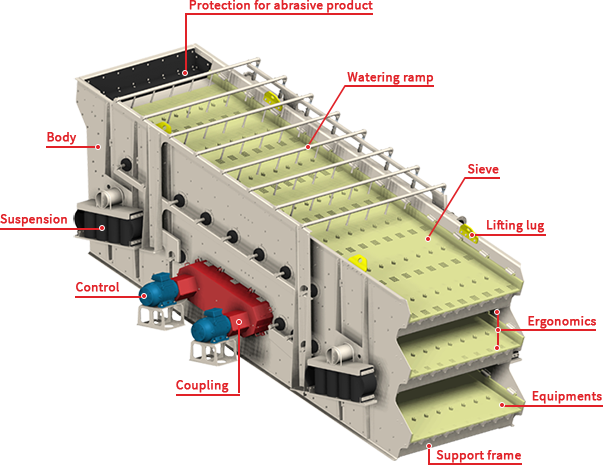

Description

• Sloping screen for any kind of classification or dry or as pulp materials.

• Excellent ability to screen "large" or "fine" any type of products or even slightly damp or clogging products (cut from 1 to 300mm).

• It combines high yield, low maintenance and low cost of exploitation.

Flow:

thousands T/hr