Dewatering Screen BIROL®

EV

Dewatering Screen BIROL® EV

Draining of solid particles contained in a pulp composed on average of 30% liquid and 70% solid.

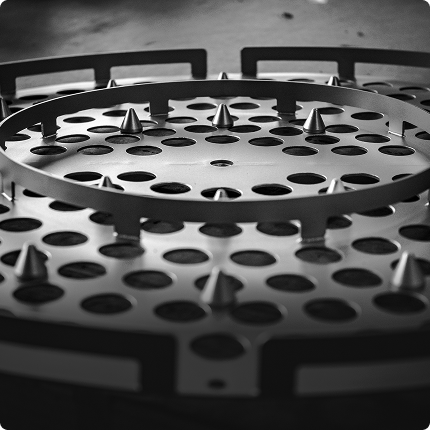

It is equipped with 2 unbalanced motors for the small models and 2 CHAUVIN BIROL type unbalanced mechanisms offering all the possibilities of vibration adjustment to adapt it to the product to be drained.

• Vibrating device suitable for draining, washing and rinsing solid particles.

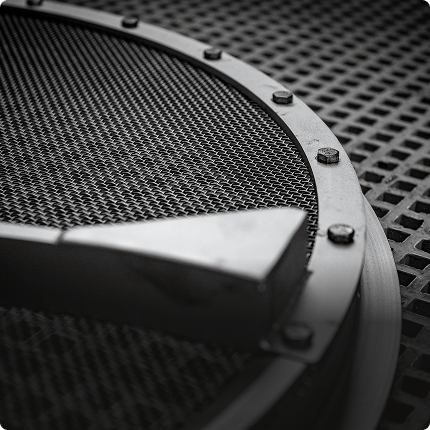

• Drainage is carried out on a metal or polyurethane grid with cracks.

The solid particles rejected by the mesh, which is a large majority, are transported under the effect of vibration, against the slope,

to the end of the device. The liquid flows through the grid from below the device.

• Washing or rinsing of the aggregates is carried out by adding a watering ramp with multiple nozzles in order to eliminate the fines stuck to the aggregates.

Flow rate : tens of t/h to hundreds of t/h.

Industries

- Agri-food

- Mineral industry

- Glassware

- Foundry sand, etc.

Characteristics

- Acceleration: 5G

- Surface area: from 1.2 to 9 m²

- Floors : 1 to 2 floors

Highlights

- Different equipment possible: modular paving stones, stainless steel crack grids

- High flow rates

- Drainage efficiency

Applications type

- Drainage of aggregates

- Washing of aggregates

- Rinsing of aggregates

Options

- Base with screened liquid recovery tank

- Thermal / hydraulic motorization

- Watering ramps

- Paint or hot-dip galvanizing finish

- Direct drive by cardan shaft with frequency variator

- Engine brake

- Lubrication center

Perfect integration into your projects

The longevity guarantee

Flexible operation

Accessible adjustment parameters

A manufacturing quality known and recognized since 1929

maintenance with remote monitoring