Heavy duty linear/elliptic motion, Grizzly Screen ROL®

Heavy duty linear/elliptic motion, Grizzly Screen ROL®

It is used on primary pre-screening stations before fragmentation.

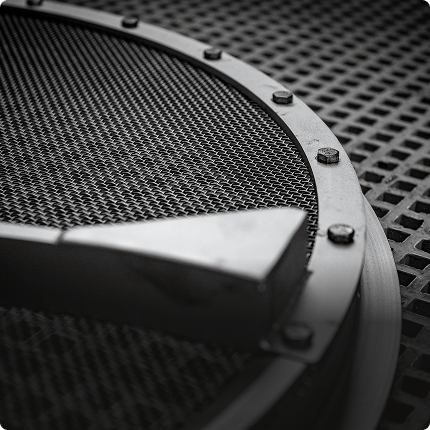

It is a very robust inclined screen equipped with diverging bars or perforated sheets mounted in cascade to tilt the blocks.

The ROL type mechanism allows rapid adjustment of the vibration amplitude .

Scalping screen for all primary station classification applications . Allows pre-screening before crushing as well as the removal of finest, dirtiest, and earth- or clay-laden materials. It combines high unit output, low maintenance , and economical operating costs.

Flow : thousands of T/h

Industries

- Mineral industry

- Career, etc.

Characteristics

- Acceleration: 3 to 4G

- Surface area: from 0.8 to 16 m²/floor

- Decks: 1 to 2 floors

Highlights

• The vibrating part or “carcass” is based on a fixed frame by the mean of elastic suspensions isolating the carcass while leaving it oscillate.

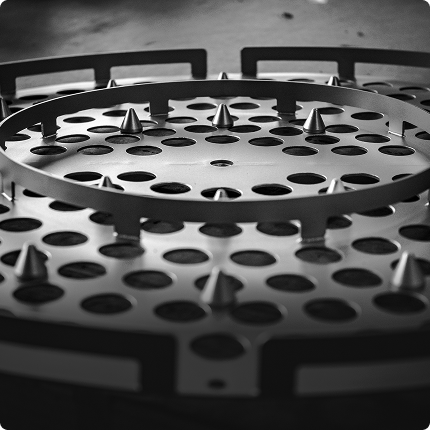

• The vibrator mechanism has 1 to 4 high speed turning shafts. Each-turn, these shafts cause a shock produced by the centrifugal force developed by counterweights.

⇒ These repeated shocks transmitted to the frame and screen cloths, create a circular vibration that operates the sorting depending on the screen mesh. The vibration is evenly distributed over the whole screening surface thus ensuring optimim efficiency at any point.

Applications type

- Granulats

- Minerais

- Phosphate, etc.

Options

- Water spraying

- “BIL-VIB” declogging device (balls)

- Finish : painting or galvanizing

- Direct drive by universal joint

- Variable speed unit

- Engine brake

- Central lubrification

- Static hood

- Flat low deck

- Hopper board

- Manhole, etc.

Perfect integration into your projects

The longevity guarantee

Flexible operation

Accessible adjustment parameters

A manufacturing quality known and recognized since 1929

maintenance with remote monitoring